High Efficiency Visual Inspection Equipment For Acoustic Components Height/Diameter Size Measuring

Visual inspection equipment is a high-speed precision automatic measuring and screening equipment which integrates vision measurement software, CCD industrial camera, machinery, industrial computer, electrical, solenoid valve blowing and other functions.

Through the automatic feeding device (vibrating plate, manipulator, belt, etc.), the workpiece to be tested and screened are transported to the detection station one by one through the material conveying device for high-speed photography. Then, the visual inspection software comprehensively evaluates and gives the calculation results. According to the preset good products and layout rules, the workpieces are divided into good and bad products. Finally, the electromagnetic valve is used to blow air into the blanking machine Bit to eliminate to different types of boxes, so as to achieve the detection and screening function of workpiece quality inspection.

Detection Function

* Workpiece size measurement.

* Workpiece appearance defect detection.

* Color recognition and defect detection.

* Character recognition(OCR) and defect detection.

* Bar code recognition and defect detection.

* Coding recognition and defect detection, etc.

Inspection Advantages

* Non-contact,no damage to the workpiece.

* High detection accuracy,up to 0.001mm.

* Fast detection speed,with 5000pcs per minute.

* Improve the overall efficiency of the enterprise.

* Save a lot of manpower and material costs.

* Fully automatic detection,stable and reliable.

* Higher corporate competitiveness.

Inspection System

--> We have independently developed visual inspection software for more than ten years. We have a core software R & D team, and continuously improve and update the software to maintain the cutting-edge advantage of new technology

--> The software functions are over 2000 kinds, including defects, color, size, copper leakage, OCR and so on. It is a quality control system that can meet the rapid detection of products in more than 100 industries.

--> Full automatic non-contact detection, no damage to the workpiece.

--> The software is programmable and can filter out 32 categories at most. Even a variety of workpieces can be completed at one time, greatly improving the overall efficiency of the enterprise.

--> The detection speed is fast, up to 5000 pieces per min, which greatly improves the working efficiency of the quality control chain.

--> In the rapid detection process, the software can also maintain ultra-high accuracy and accuracy, according to the different workpiece, up to 1um.

--> From detection to screening and even packaging, there is no need for redundant manual operation, which saves labor cost, reduces human impact in the process of quality control, and greatly improves the accuracy.

--> Intelligent software, friendly operation page, simple operation, table can choose simulation data, enhance the rapid contrast processing of large batch of data, and connect with ERP system, improve the efficiency of enterprise data processing, at a glance.

Appearance defect detection

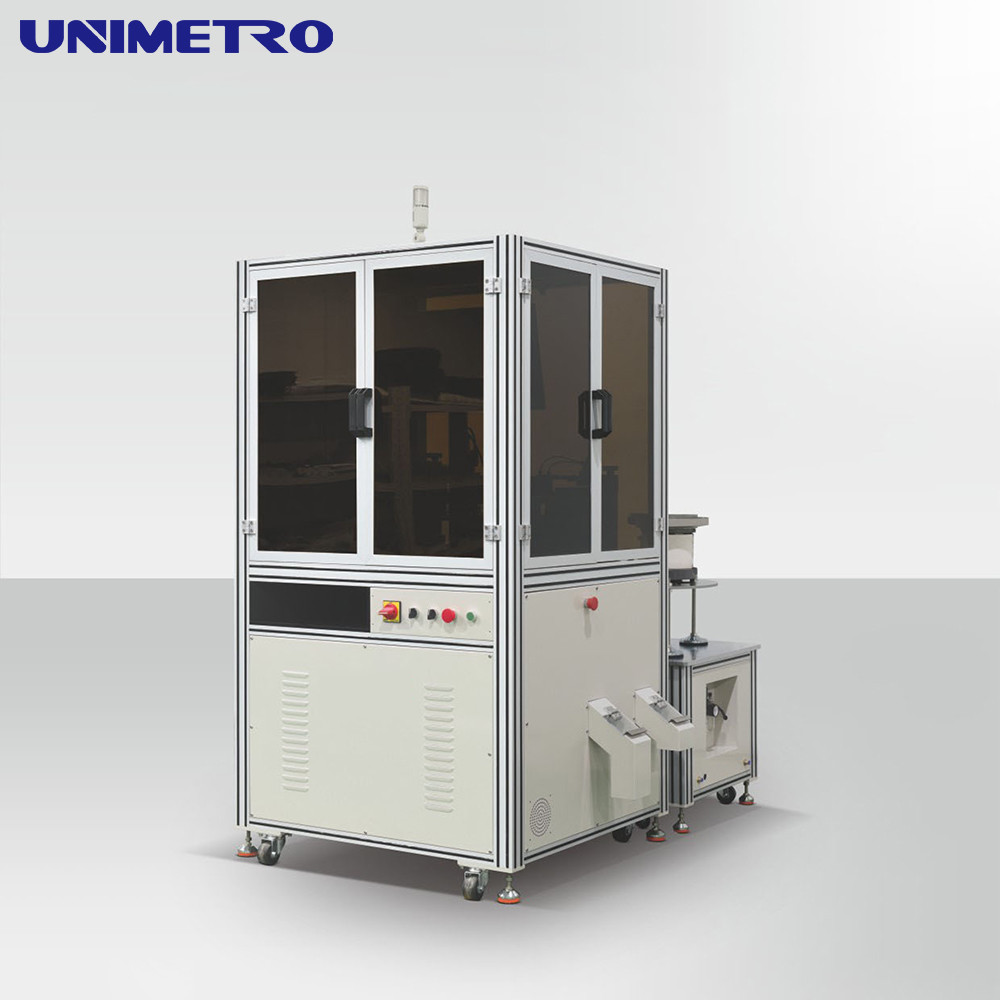

Acoustic Components Visual Inspection Equipment

UNIMETRO Acoustic component visual inspection equipment, provide effective solutions for various appearance defects and dimensional quality problems in the manufacturing process of various speaker pole piece, porcelain bowl, injection molding bracket and other products.

Automatic visual inspection of various mobile speaker parts appearance defects and dimensions, and intelligent output of inspection reports.

For speaker parts manufacturers to optimize the production process, reduce production costs, and ultimately ensure that the products have perfect quality.

Product

Various speaker parts, pole pieces, porcelain bowls, porcelain bowl pole piece assemblies, speaker brackets, etc.

Size:900*1000*1800mm(L*W*H)

Weight:300kg

Feature

1. Automatically detect the appearance defects and dimensions of commutator.

2. All testing items are tested at one time.

3. High versatility, a single device can detect multiple commutator products.

4. Industry-leading defect detection for commutator appearance.

5. Detection speed can reach 800 pieces per minute.

6. Detection accuracy can reach to 0.001mm.

7. Automatic classification and blanking of good and defective products.

8. Automatic feeding and equipped with automatic feeding storage hopper, greatly reducing the frequency of manual feeding.

9. Equipped with imported optical components such as Germany, Japan and Italy.

10. Intelligent output test form to help improve lithium commutator production process.

11. Easy to learn and use, you can work independently after 1-2 days of simple training.

12. 7x24 hours of uninterrupted work.

Parameters

| Size detection |

Height, length, width, aperture, inner length and width, outer length and width, step size, etc.

|

| Exterior detection |

Corner deformation, overall deformation, front and back defects, poor assembly, missing magnets, missing poles, magnets eccentricity, defects, fractures, excessive glue, front burrs, mixed materials, etc.

|

Company Information

Our Client&Agent

| FAQ |

Q1: Are you a factory or trading company ? Q1: Are you a factory or trading company ? |

A1: We are a factory and giving you the quickest reply in 24 hours. A1: We are a factory and giving you the quickest reply in 24 hours. |

Q2: What's your company mainly in? Q2: What's your company mainly in? |

A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. |

Q3: How to Choose the Appropriate Specification? Q3: How to Choose the Appropriate Specification? |

A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. |

Q4: Do you accept customized service? Q4: Do you accept customized service? |

A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. |

Q5: What is your warranty period? Q5: What is your warranty period? |

A5: Our product warranty period is 1 year. Our product quality is very stable, and we have A5: Our product warranty period is 1 year. Our product quality is very stable, and we have

improved a lot on some breakable parts. You can rest assured of our product quality. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!