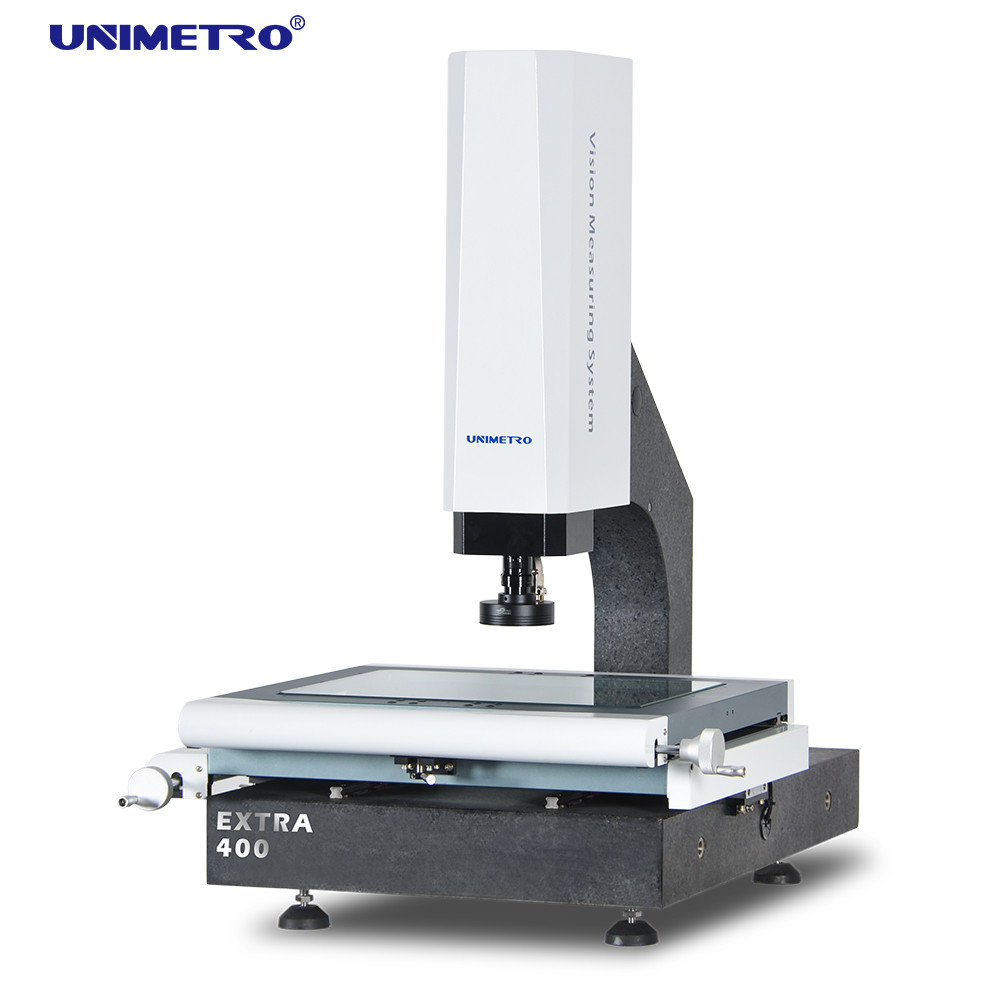

Z-axis with Auto Focusing VMS Vision Measuement Systems

DESCRIBING

EXTRA series semi-automatic vision measuring machine provides customers with measurement function and user experience beyond ordinary products. Full range of z-axis servo control, the standard configuration of hand pulse generator for fine control and fine-tuning of Z-axis motion, with automatic image focusing function, your measurement efficiency and user experience are greatly improved.

Parameters

| Model |

EXTRA 200 |

EXTRA 300 |

EXTRA 400 |

EXTRA 500 |

| Dimension(mm)(L*W*H) |

500*540*930 |

600*740*980 |

700*840*980 |

800*940*980 |

| Measuring range (mm)(X*Y*Z) |

200*100*150 |

300*200*200 |

400*300*200 |

500*400*200 |

| Measuring Accuracy (μm) |

2.5+L/100 |

2.5+L/100 |

2.5+L/100 |

3+L/100 |

| Repeatability (μm) |

2.5 |

2.5 |

2.5 |

3 |

| Weight (kg) |

140kg |

190kg |

240kg |

290kg |

| Image and Measuring |

CCD |

200mm (can be raised according to the requirements of customers) |

| Lens |

Manual dented zoom lens 0.7-4.5X/Auto zoom lens 1-10X |

| Magnification |

18-195X ( For reference only. With different camera and lens the magnification will be different. ) |

| Field of View |

8.1~1.3mm |

| Working distance |

108mm |

| Linear scale resolution |

0.5 μm( 0.1μm for option ) |

| Driving system |

X , Y axis manual conrol , Z axis close-loop CNC control and AUTU FOCUS funtion available |

| Illumination |

Programmable 4 sections LED ring surface light , parallel LED contour light , 8 sections LED ring light , co-axial , for option |

Features

◆ Quality details control

1. Granite base and column, excellent stability;

2. Aluminum work stage, make the motion control fast reacting and flexible;

3. Work stage with hard oxidation surface processing anti-scratch;

4. Standard with precision linear guide, grinding ball screw and AC servo motor etc., to ensure the precision and stability of the motion system;

5. Integrated control system, embedded with motion control, and all signal control as illumination and linear scale reading, ensures the performance of the machine is extremely stable.

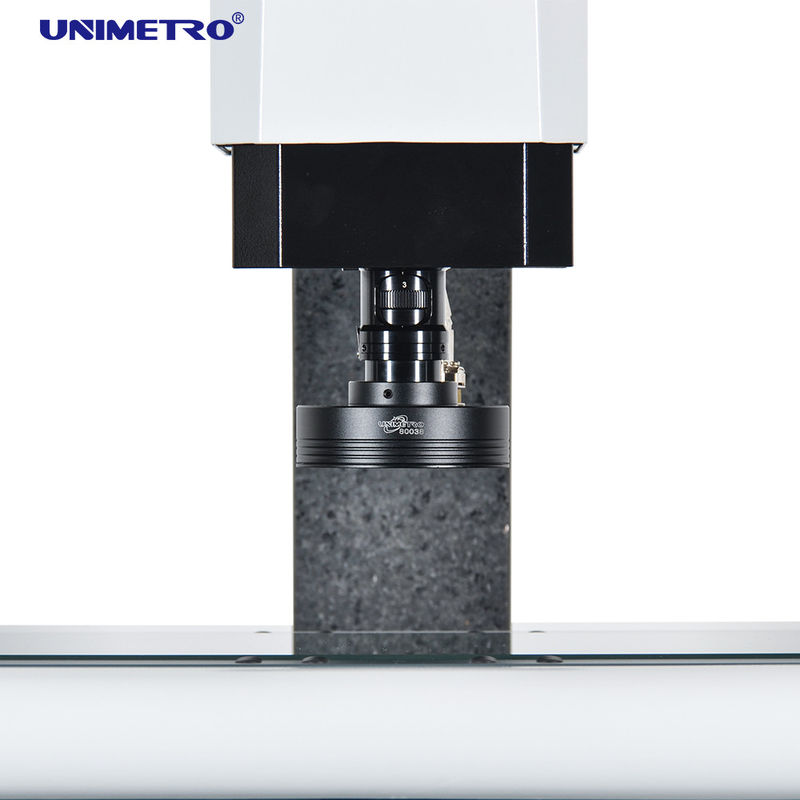

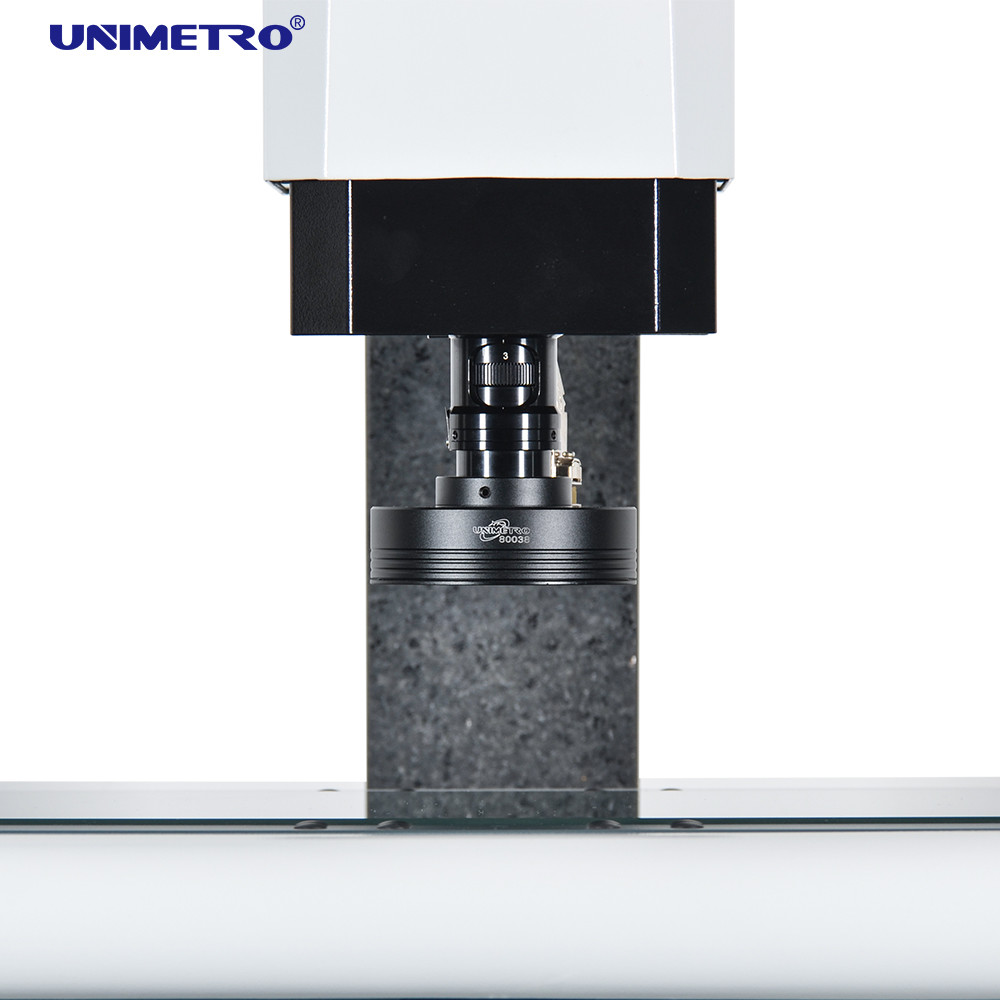

◆ High performance configuration

1. X, Y two-axis manual control to achieve accurate positioning;

2. The Z-axis adopts high-precision linear guide and servo motor control system to realize automatic focusing, eliminate the error of artificial focusing, and improve the measurement accuracy and stability;

3.0.5um high-precision linear ruler and precision worktable ensure that the accuracy of the machine is ≤ 2.5 + L / 100um;

4. High precision toothless polished rod and fast moving locking device are used to ensure the return error of worktable within 2um;

5. Industrial high-resolution color CCD ensures clear image quality without distortion and meets the needs of clear observation and accurate measurement;

6. 0.7-4.5x HD zoom manual electronic feedback signal zoom lens, the software canquickly and automatically identify the magnification and carry out the corresponding zoom action, making the measurement steps simpler;

◆ Efficient measurement software

1. EXTRA Series vision measurement machine is campatible with multiple option of powerful measuring software. Which are with diversified measuring function, can measure geometric elements such as points, circles, lines, angles, angles, etc., as well as dimensions such as distance, roundness, straightness, concentricity, etc.

2. Simple and easy to understand operation interface makes measurement more simpleand efficient;

3. CAD file input and comparing, easy output of measuring report, and SPC analyse of the measuring results data

◆ Flexible expansibility

1. Extra series CMM is compatible with Renishaw probe series (optional), and users can easily realize two-dimensional and three-dimensional measurement functions on one machine. The software can calculate the offset between the optical lens and the touch probe to ensure that all measurement results are in one coordinate system.

2. The measurement results can be output to 3D graphics for reverse engineering application.

3. A variety of non-contact sensors and quick fixing system can be selected to meet different measurement requirements of different customers

4. Green contour light can be selected to make it more flexible and powerful for different parts of different materials or shapes, and provide more powerful measurement applications.

Company Information

Our Client&Agent

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!