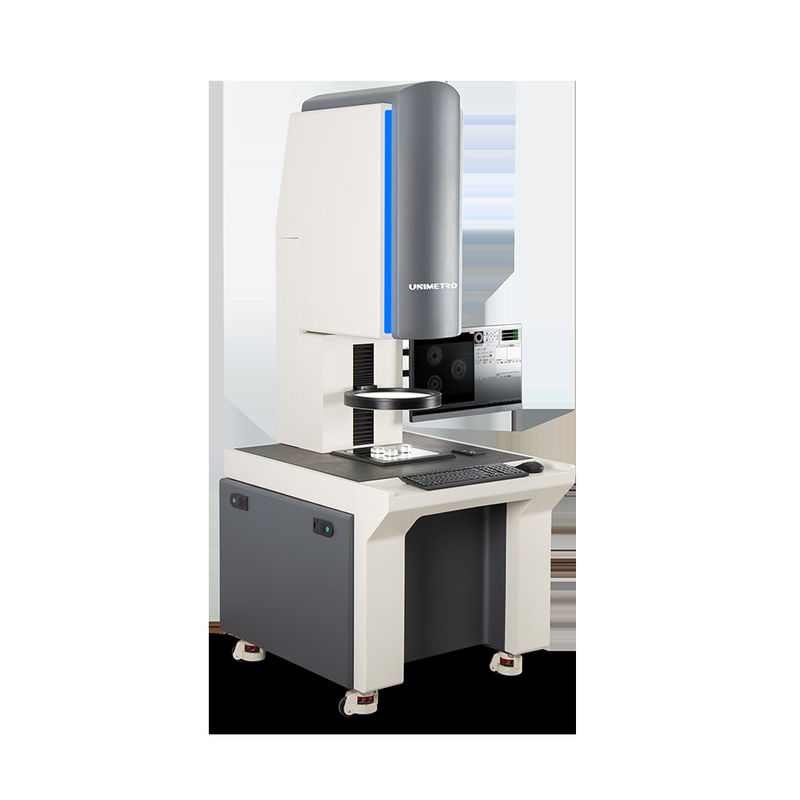

Surface Roughness Contour Tester Roughness Contour Measuring machine Roughness measurement profilometer machine

Product Description

Roughness profile measurement analysis basis

The measurable elements of all surfaces include size, shape, roughness and waviness. Many high-profile components need to analyze all of the above elements.

◆ Dimensions: Surface functional shapes defined by the linear relationship between radius, angle, distance, and features.

◆ Shape: deviation from the target shape of the surface (plane, sphere, cone, etc.), usually caused by machine error

◆ Roughness: caused by factors such as cutting tools or machining processes

◆ Waviness: Non-ideal machine effect caused by vibration, insufficient rigidity or other unstable factors in the process

SPR1000 Series

Characteristics:Standard type, low cost of use.

Using a digital contour sensor and an inductive standard roughness sensor dual sensor, a machine can be used to measure contour and roughness.

Measuring Case

Articulated arm bearing Optical grade germanium crystal

Seal ring Turbo seal

Recommended Size

| Specification number | PR1103G-sdk |

| Measuring range | X-axis | 100mm |

| Z-axis | 320mm |

| Z1-axis | C:±12.5mm/R:±420μm |

| Contour accuracy | Z1 Linear precision1 | ±(1.5+|0.2H|)μm |

| Arc | ±(2+R/8)μm |

| angle | ±2′ |

| Straightness | 0.8μm/100mm |

| Roughness accuracy | Linear precision | ±4% |

| Residual noise | ≤0.02μm |

| Duplicate value | 1δ≤2nm |

| Cutoff wavelength | 0.025,0.08,0.25,0.8,2.5,8mm |

| Rating length | λcX2,3,4,5,6,7 |

| Drive speed | X-axis | 0.1~10mm/s |

| Z-axis | 0.5-10mm/s |

| Measurement function | Profile | Line elements of various types of workpiece surfaces, point features, distance between points and points, distance between lines and lines, position of each element including distance, parallelism, perpendicularity, angle, groove depth, groove width, radius, can be performed Straightness analysis, convexity analysis, profile analysis |

| Roughness | Roughness function:Ra,Rp,Rv,Rz(jis),R3z,RzDIN,Rzj,Rmaz,Rc,Rt,Rq,

Rsk,Rku,Rsm,Rsm,Rs,RΔq,Rk,Rpk,Rvk,Mr1,Mr2,Rmr

Waviness parameter:Wa,Wt,Wp,Wv,Wz,Wq,Wsm,Wsk,Wku,Wmr

Original contour parameter:Pa,Pt,Pp,Pv,Pz,Pq,Psm,Psk,Pku,Pmr |

● Rail travel:100-150mm

● Number interval: 0.2~2µm

● Contour straightness:0.5µm/100mm

● Roughness residual value:≤0.02µm

● Maximum moving speed:10mm/s

● Minimum measurement speed:0.1mm/s

● Feature description:Standard drive, performance can meet the requirements of part-level contour measurement accuracy, with roughness sensor can meet the measurement needs of Ra greater than 0.1 microns

Column member: Cns standard type column / Cnsl standard type long column

(Can choose according to your needs)

● Range:320~420mm / 520~620mm

● Maximum moving speed:10mm/s

● Minimum moving speed:0.5mm/s

● Positioning accuracy:0.01mm

● Feature description:Lightweight design, frame-type column, long-term use without deformation

Platform components: Mpm integrated standard machine

● Material:marble

● Specification:500*800,500*1000

● Feature description:One-piece design, compact structure, easy maintenance and saving

With a contact-type roughness meter, surface roughness is measured by tracing the probe across the surface of the target. In contrast, a laser-based non-contact roughness meter emits a laser beam onto the target and detects the reflected light to measure the roughness

A roughness tester is used to quickly and accurately determine the surface texture or surface roughness of a material. A roughness tester shows the measured roughness depth (Rz) as well as the mean roughness value (Ra) in micrometers or microns (µm).

Company Information

Our Client&Agent

| FAQ |

Q1: Are you a factory or trading company ? Q1: Are you a factory or trading company ? |

A1: We are a factory and giving you the quickest reply in 24 hours. A1: We are a factory and giving you the quickest reply in 24 hours. |

Q2: What's your company mainly in? Q2: What's your company mainly in? |

A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. |

Q3: How to Choose the Appropriate Specification? Q3: How to Choose the Appropriate Specification? |

A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. |

Q4: Do you accept customized service? Q4: Do you accept customized service? |

A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. |

Q5: What is your warranty period? Q5: What is your warranty period? |

A5: Our product warranty period is 1 year. Our product quality is very stable, and we have A5: Our product warranty period is 1 year. Our product quality is very stable, and we have

improved a lot on some breakable parts. You can rest assured of our product quality. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!