Surface Roughness Tester Contour Measuring System

Product Description

Roughness profile measurement analysis basis

The measurable elements of all surfaces include size, shape, roughness and waviness. Many high-profile components need to analyze all of the above elements.

◆ Dimensions: Surface functional shapes defined by the linear relationship between radius, angle, distance, and features.

◆ Shape: deviation from the target shape of the surface (plane, sphere, cone, etc.), usually caused by machine error

◆ Roughness: caused by factors such as cutting tools or machining processes

◆ Waviness: Non-ideal machine effect caused by vibration, insufficient rigidity or other unstable factors in the process

SR1000 Series

Features: desktop standard type, low cost of use

● With leadless standard inductive sensor

● Can evaluate hundreds of parameters such as roughness, waviness and profile

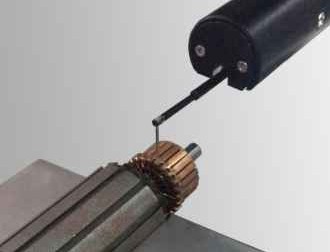

Measuring Case

Commutator Screwdriver handle

Valve Bearing

Recommended Size

| Specification number | SR1133G-sak |

| Measuring range | X-axis | 100mm |

| Z-axis | 320mm |

| Z1-axis | ±420µm/65536:1 |

| Roughness parameter | Z1 Linear precision | ±4% |

| Repeatability | 1δ≤2nm |

| Cutoff wavelength

| 0.025,0.08,0.25,0.8,2.5,8mm |

| Rating length | λcX2,3,4,5,6,7 |

| Residual noise

| ≤0.005µm |

| Drive speed |

X-axis |

0.1~10mm/s |

| Z-axis | 0.5-10mm/s |

| Measurement function | Roughness | Roughness function:Ra,Rp,Rv,Rz(jis),R3z,RzDIN,Rzj,Rmaz,Rc,Rt,Rq,Rsk,Rku,Rsm,Rsm,Rs,RΔq,Rk,Rpk,Rvk,Mr1,Mr2,Rmr

Waviness parameter:Wa,Wt,Wp,Wv,Wz,Wq,Wsm,Wsk,Wku,Wmr

Original contour parameter:Pa,Pt,Pp,Pv,Pz,Pq,Psm,Psk,Pku,Pmr |

System Components

Sensor: R series no head standard Inductance Sensor

● Resolution ratio:65536:1/262144:1

● Range:±420µm/±620µm

● Linear precision:R:±4%/±3%

● Residual noise:≤0.007µm/≤0.005µm

● Roughness reference:Guide,No lead

● Feature description:No-head roughness sensor, good frequency response characteristics, wide signal bandwidth, is the best roughness sensor type.

Driver: DS standard driver / Dc ceramic driver(Can choose according to your needs)

● Rail travel:100-150mm

● Number interval: 0.2~2µm

● Contour straightness:0.5µm/100mm

● Roughness residual value:≤0.02µm

● Maximum moving speed:10mm/s

● Minimum measurement speed:0.1mm/s

● Feature description:Standard drive, performance can meet the requirements of part-level contour measurement accuracy, with roughness sensor can meet the measurement needs of Ra greater than 0.1 microns

Column member: Cns standard type column / Cnsl standard type long column

(Can choose according to your needs)

● Range:320~420mm / 520~620mm

● Maximum moving speed:10mm/s

● Minimum moving speed:0.5mm/s

● Positioning accuracy:0.01mm

● Feature description:Lightweight design, frame-type column, long-term use without deformation

Platform components: Mpm integrated standard machine

● Material:marble

● Specification:500*800,500*1000

● Feature description:One-piece design, compact structure, easy maintenance and saving

Company Information

Our Client&Agent

| FAQ |

Q1: Are you a factory or trading company ? Q1: Are you a factory or trading company ? |

A1: We are a factory and giving you the quickest reply in 24 hours. A1: We are a factory and giving you the quickest reply in 24 hours. |

Q2: What's your company mainly in? Q2: What's your company mainly in? |

A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. |

Q3: How to Choose the Appropriate Specification? Q3: How to Choose the Appropriate Specification? |

A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. |

Q4: Do you accept customized service? Q4: Do you accept customized service? |

A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. |

Q5: What is your warranty period? Q5: What is your warranty period? |

A5: Our product warranty period is 1 year. Our product quality is very stable, and we have A5: Our product warranty period is 1 year. Our product quality is very stable, and we have

improved a lot on some breakable parts. You can rest assured of our product quality. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!