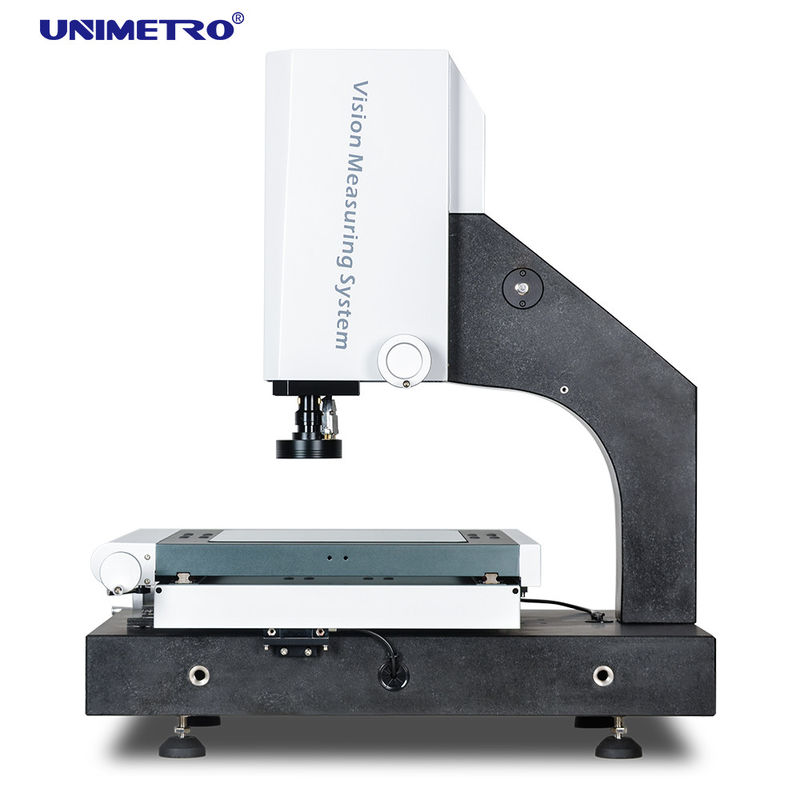

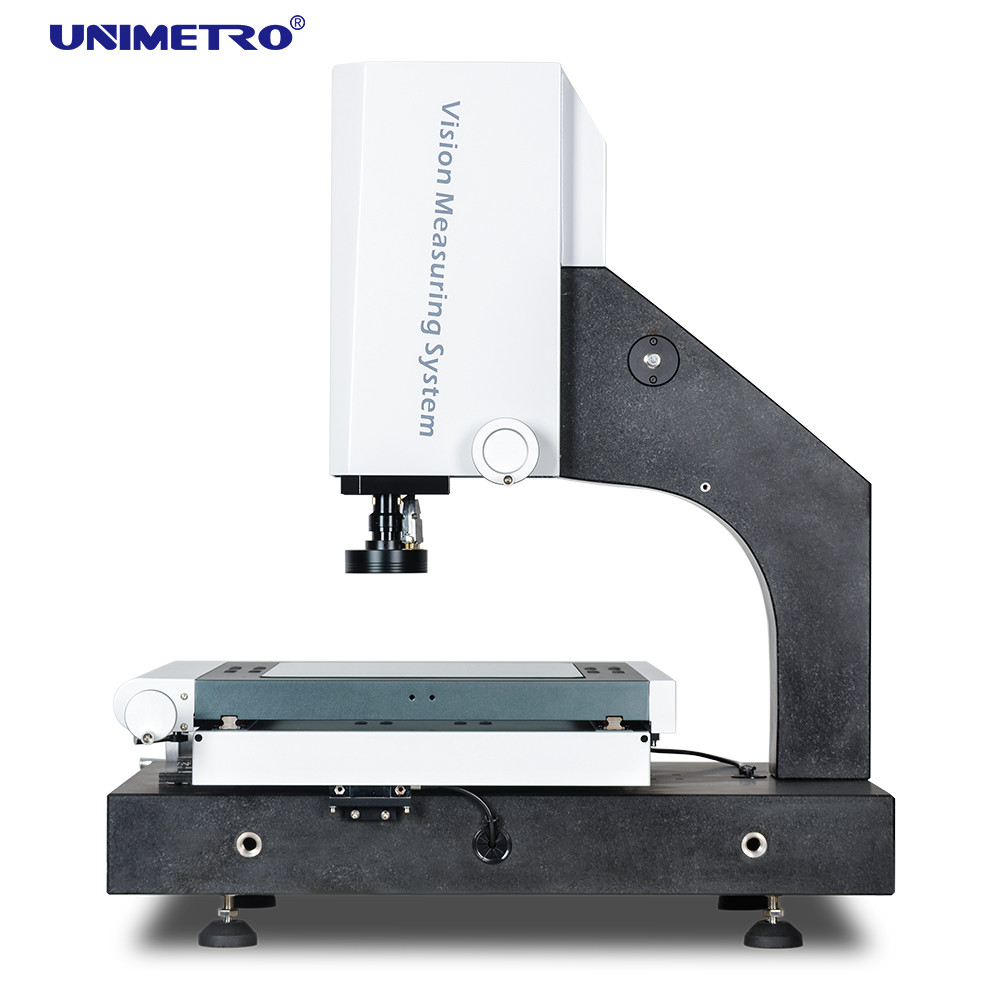

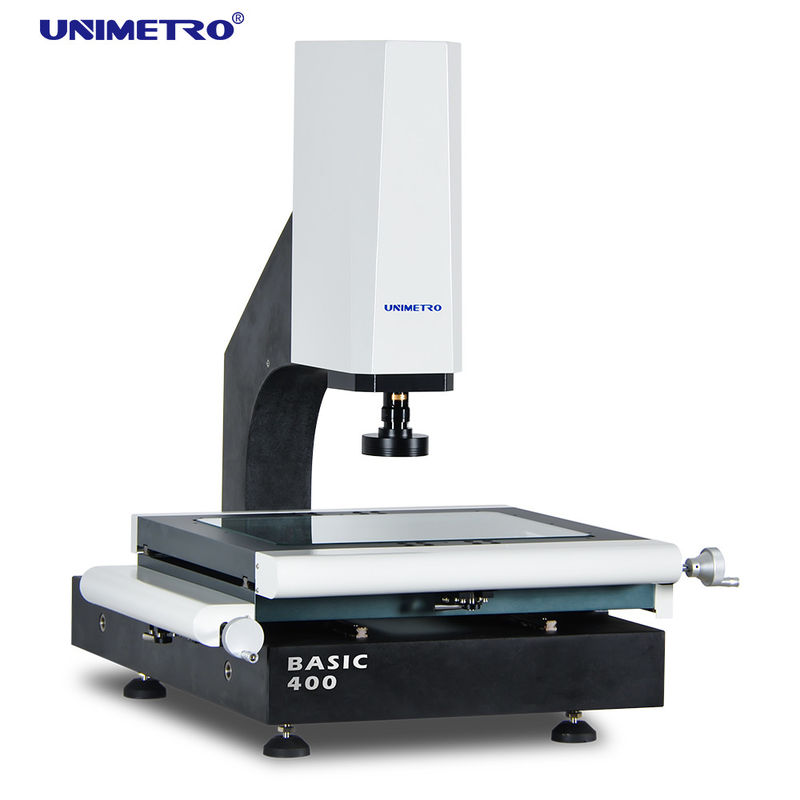

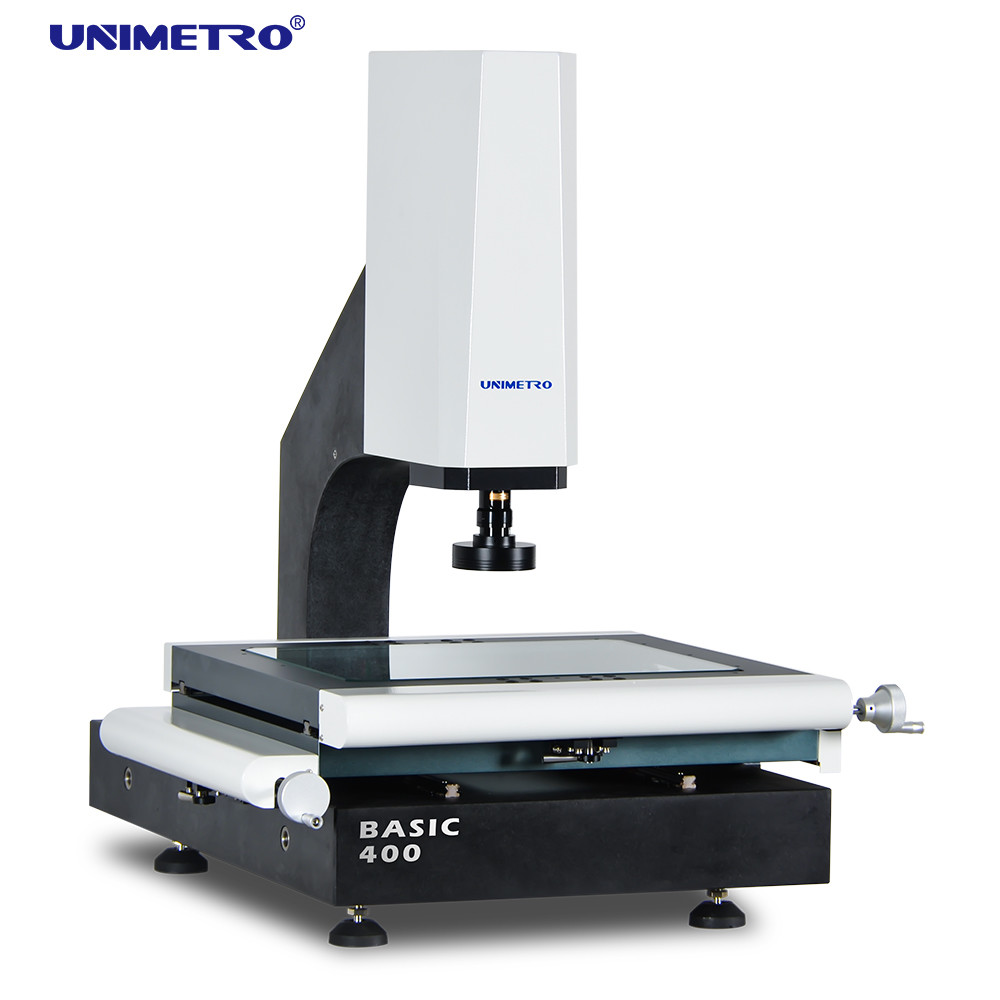

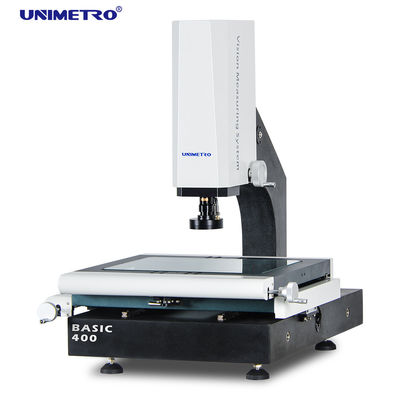

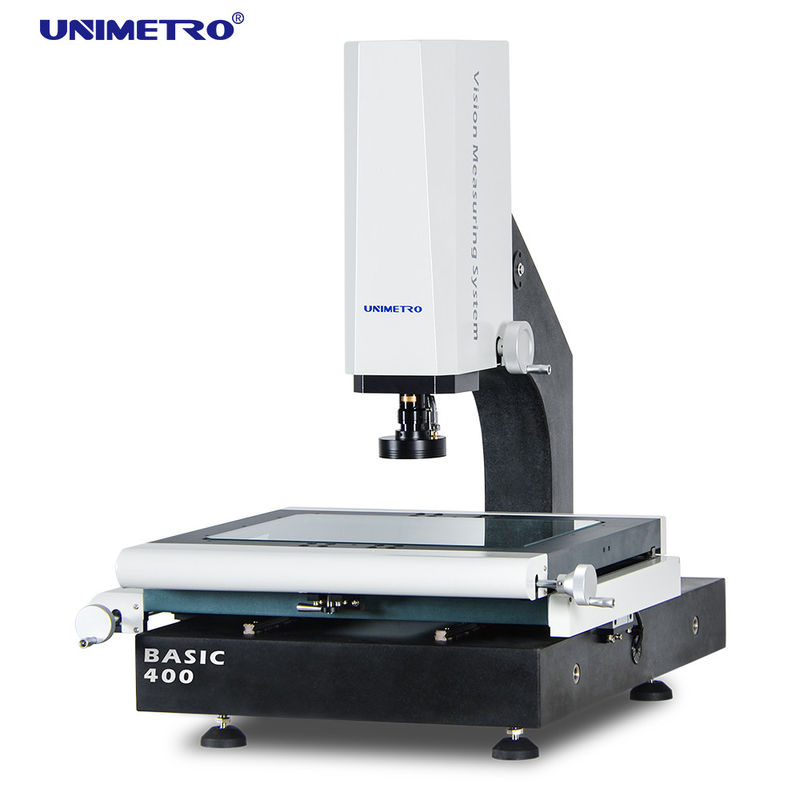

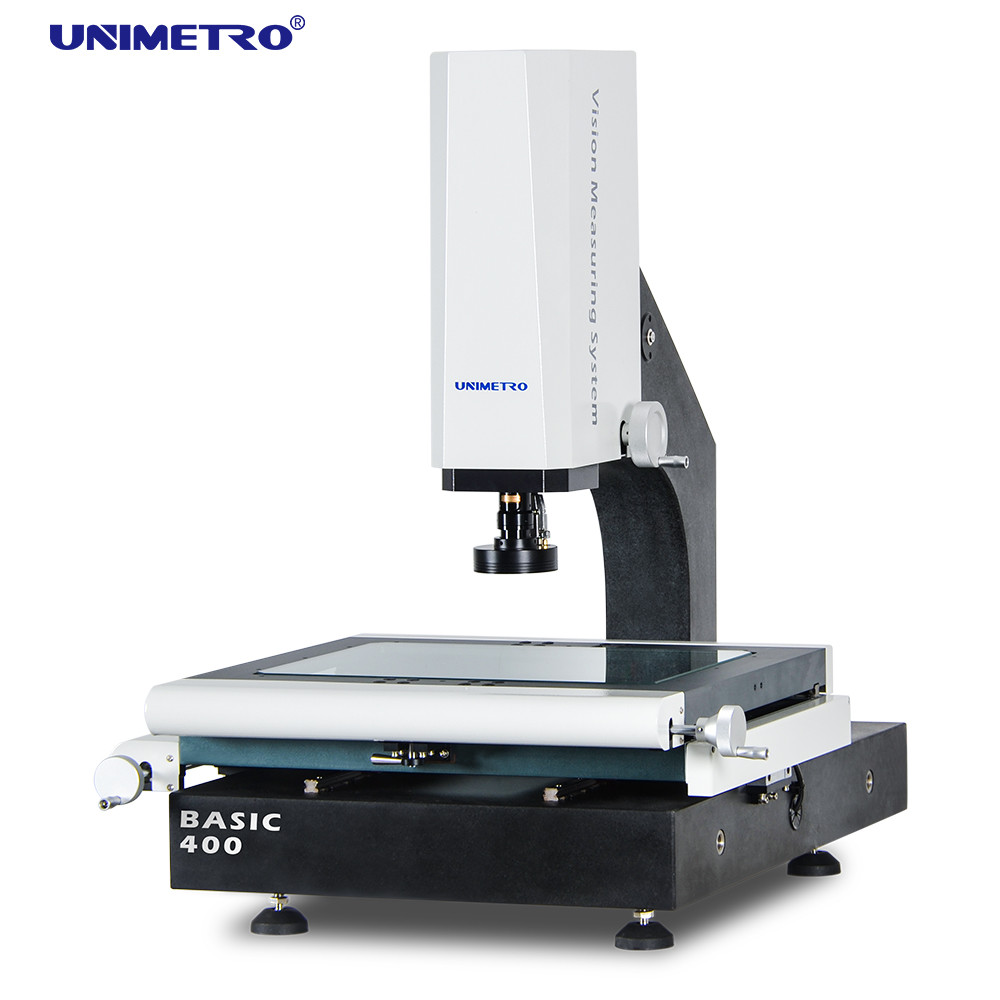

Good quality optical measurement equipment manual vision measurement machine vmm machine

manual vision measurement machine can be operated as below video shows

Descrition

▶ Granite base and column, excellent stability;

▶ Aluminum work stage,make the motion control fast reacting and flexible;

▶ Using HIWIN linear guide way and high-precision linear guide rail, with aluminum work stage and hard anodizing surface processing, ensures the high dynamic performance and long life cycle usage of the machine.

▶ Integrated control system,embedded with motion control,and all signal control as illumination and linear scale reading, ensures the performance of the machine is extremely stable.

◉ 3 axis 0.5um resolution linear scales

◉ High performance Auto focus function

◉ Compatible with Renishaw touch probe

◉ Aluminum work stage and hard anodizing

◉ 3 rings 8 section LED ring light software control and programmable

◉ Parallel light path LED contour light software control and programmable

◉ 1.2M pixel HD digital camera

◉ Integrated core control box

◉ Z axis motorized control

◉ HIWIN linear guide way

◉ With Laser indicators for auxiliary positioning and focusing

◉ 0.7-4.5X manual dented zoom lens with magnification signal feedback sensor

Probe Features

Our manual vision measurement machine can realize 3D function by adding probe.

◉ Easy calibration

◉ Multiple angle touching

◉ Fast coordinates system setting

◉ Compatible to full line of Renishaw stylis

◉ CAD module supported(Optional)

◉ 3D drawing output

◉ Star probe compatible

◉ 3D dimension measuring

◉ Image and touch probe combine measuring

◉ Probe rack supported(Optional)

Parameters

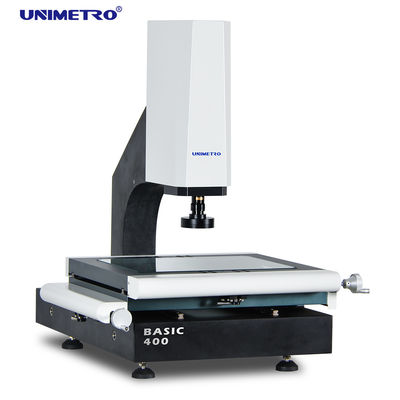

| Model |

BASIC 200 |

BASIC 300 |

BASIC 400 |

BASIC 500 |

| Dimension(mm)(L*W*H) |

550*540*930 |

600*740*980 |

700*840*980 |

800*940*980 |

| Measuring range (mm)(X*Y*Z) |

200*100*150 |

300*200*200 |

400*300*200 |

500*400*200 |

| Measuring Accuracy (μm) |

2.5+L/100 |

2.5+L/100 |

2.5+L/100 |

3+L/100 |

| Repeatability (μm) |

2.5 |

2.5 |

2.5 |

3 |

| Weight (kg) |

140kg |

190kg |

240kg |

290kg |

| Image and Measuring |

CCD |

1.2M pixel HD digital camera |

| Lens |

0.7-4.5X manual dented zoom lens with maganification signal feedback sensor |

| Magnification |

18-195X ( For reference only. With different camera and lens the magnification will be different. ) |

| Field of View |

8.1~1.3mm |

| Working distance |

80mm |

| Linear scale resolution |

0.5 μm( 0.1μm for option ) |

| Driving system |

X,Y,Z axis manual control |

| Illumination |

Programmable 4 sections LED ring surface light , parallel LED contour light , 8 sections LED ring light , co-axial , for option |

L is measuring length(mm), the mechanical accuracy of Z-axis and focus accuracy is related to the surface of the workpiece. **Magnification is approximate value, it is related to the dimension of monitor and resolution.

Field of view(mm) = (diagonal*Horizontal*Vertical)

0.5X or 2X objective is optional available, and realize image magnification: 13X~86X or 52X~344X.

Software Function

The UNIMETRO INSPECT3D software is with user friendly UI, easy to learn,

powerful function, allows the users to achieve fast and precise measuring.

The software is offering full English language UI, also allows new language development

◉ Input CAD file and measure

◉ Parts array and macro measuring

◉ Auto focus and height measuring

◉ Navigating function helps fast locating

◉ Powerful geometric measuring function

◉ Multiple data reports and graphical data output function

◉ Flexible user program

◉ Creating reference elements

◉ Powerful edge detecting function

◉ Supporting multiple external accessories

◉ Auto calculation of the elements geometrical tolerance

◉ Measuring complicated production fast and conveniently

Company Information

Our Client&Agent

| FAQ |

Q1: Are you a factory or trading company ? Q1: Are you a factory or trading company ? |

A1: We are a factory and giving you the quickest reply in 24 hours. A1: We are a factory and giving you the quickest reply in 24 hours. |

Q2: What's your company mainly in? Q2: What's your company mainly in? |

A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. |

Q3: How to Choose the Appropriate Specification? Q3: How to Choose the Appropriate Specification? |

A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. |

Q4: Do you accept customized service? Q4: Do you accept customized service? |

A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. |

Q5: What is your warranty period? Q5: What is your warranty period? |

A5: Our product warranty period is 1 year. Our product quality is very stable, and we have A5: Our product warranty period is 1 year. Our product quality is very stable, and we have

improved a lot on some breakable parts. You can rest assured of our product quality. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!