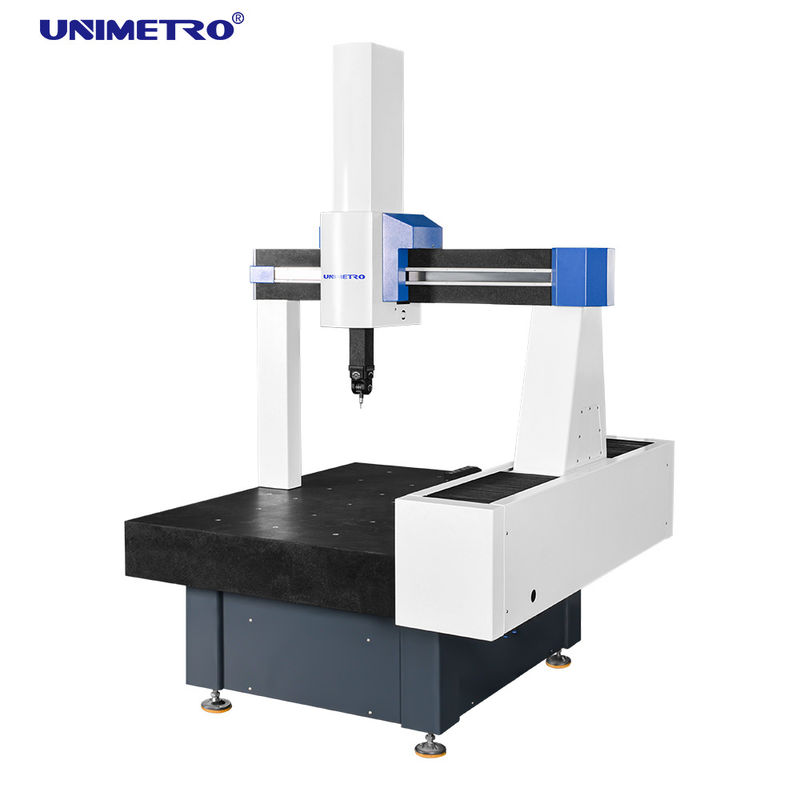

High Precision 600*800*400mm 3D CMM Machine

Se-Mi Manual Coordinate Measuring Machine With MH20i Probe

INTRODUCTION

“Helium” is characterized by the highest precision machine which is UNIMETRO wholly developed and designed. Each part is selected strictly in the period of manufacturing and make sure that all parts are connected perfectly and opportunely in the period of assembly. The acceptance of measuring machines takes place according to ISO 10360-2. In doing so, two standardized acceptance procedures are used. All measuring machines are measured with an ultra precision laser. Afterwards, a test conforming to standards with DKD-certified solid measures such as gauge blocks, ball plates, etc. is conducted. Therefore, the machine customers use at last is real high quality,high precision and German Technology.

TECHNICAL PARAMETERS

Measuring area : X=610mm, Y=813mm, Z=410mm

Overall dimension: 1350 X 1580 X 2680 mm

Max Part Weight: 900kg

Machine weight: 2080kg

MPEe: ≤ 1.8+L/350 (μm)

MPEp: ≤ 2.3μm

Scale resolution: 0.5um

Max 3D Speed: 520mm/s

Max 3D Acceleration: 900mm/s

ADVANTAGES

Patent double passive vibration damping:

CMM is mostly used in the company and near by the other machines and transport truck. The vibration influences the precision of CMM. Make a special foundation is one solution but this will cost and trouble. Our CMM has the patent support with double passive vibration damping Integrated directly in the machine frame. Thus the machine may be suitably positioned close to production. No need the special foundation for this CMM in most cases.

High quality granite worktable:

Worktable is the support of all the CMM, its quality is important for the performance! Our CMM is made with high precision, heavy and stable natural granite worktable from “Mount TAI”; this can support vibration damping and improve the performance of CMM.

Enclosed guides in all axes:

The environment of the CMM has strict requirement, but some different such as the temperature and dust are possible in the measurement room. As a standard, all our CNC machines are fitted with enclosed guides. This protects the guide ways from damage, dirt, and direct thermal influences. This can prevent external dust and temperature changes. It’s important for usage in dusty environment.

Friction “automatic rectifying” transmission:

Our CMM uses friction transmission, and has the “automatic rectifying” system in all axes. The transmission system using “fixed + micro suspension” structure to ensure transmission is parallel with guide way. That makes the measuring machine largely maintenance-free.

Imported key parts:

Key parts are most important for the stable of machine. Only with the best design and best quality of key parts can make the long time stable of CMM. All the key parts are famous brands(servo motor, transmission system, pneumatic system etc.). This can make best precision and service life of the CMM.

RENISHAW optical scale:

Optical scale is one of most important part for CMM; RENISHAW is the best flag in the domain of CMM parts. It has the best products and best service reputation! Our CMM use always RENISHAW high accuracy optical scale. Resolution is 0.05 um.

Air bearing surround guide way in all 4 sides:

Air bearing guide way using 4 sides surrounded structure! This is the symbol of stable and quality! In our CMM, each axis has many air pressure regulators in different directions and pneumatic bearings, annular pneumatic bearing design guaranties instruments steady during moving.

Small holes technology:

Air consumption: 150NL/Min. Small holes technology, this makes condensate zone between air bearing and guide way. It can offset the little heat comes from the motion friction! This technology improves the thermal stability of the CMM and keeps the long term precision stability.

SOFTWARE

Rational-DMIS

Rational - DMIS is a newly developed large-scale integrated 3D measurement software package. In addition to the development and design of studio software, which takes into account the requirements of beginners for easy learning and use of the software and the functional requirements of high-level users for the software, more importantly, it has become a model for CMM measurement software standardization.

Rational DMIS programs are designed with the full and native DMIS kernel until version 5.0 of DMIS, which is totally different from the so-called "support DMIS" (the kernel is not DMIS). As we all know, DMIS has become an ISO standard (ISO 22093:2003)

PROBE FUNCTION

Probe head :MH20i manual head by RENISHAW

Repeatability of position: +0.5 μm

Positioning steps: 15°

Rotating axis : +180°

Swing axis : 0°- 90°

With EM2 maximum extension: 140mm

Operational environment temperature: 10-40℃

Probe :TP20 SF module

Probe: M2 probe assembly

| Number |

Name |

Specifications |

Qty |

| A-5004-7585 |

Probe extension rod |

10mm |

1 |

| A-5004-7586 |

Probe extension rod |

20mm |

2 |

| A-5000-2280 |

Probe extension rod |

40mm |

1 |

| A-5000-7805 |

Ball probe |

Φ0.7×10mm |

2 |

| A-5000-3603 |

Ball probe |

Φ2×20mm |

2 |

| A-5000-3604 |

Ball probe |

Φ3×10mm |

2 |

| A-5000-4161 |

Ball probe |

Φ4×20mm |

1 |

| A-5000-2286 |

Ball probe |

Φ5×50mm |

1 |

| |

Probe spanner |

|

2 |

| Total: |

9 Type |

|

14 pc |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!