1) Vision measurement machine is an instrument used for accurate physical dimension measuring, accuracy up to micron level.

2) Vision measurement machine an optical measuring instrument using the camera to capture the image of the work piece, analyse the image pixel and calculate the 2D dimension with the measuring software.

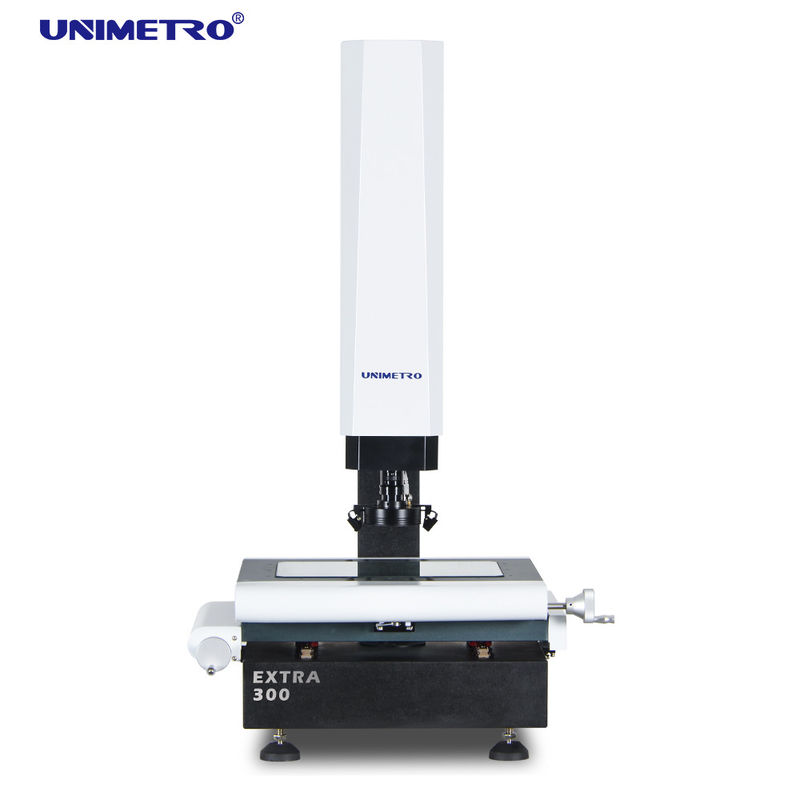

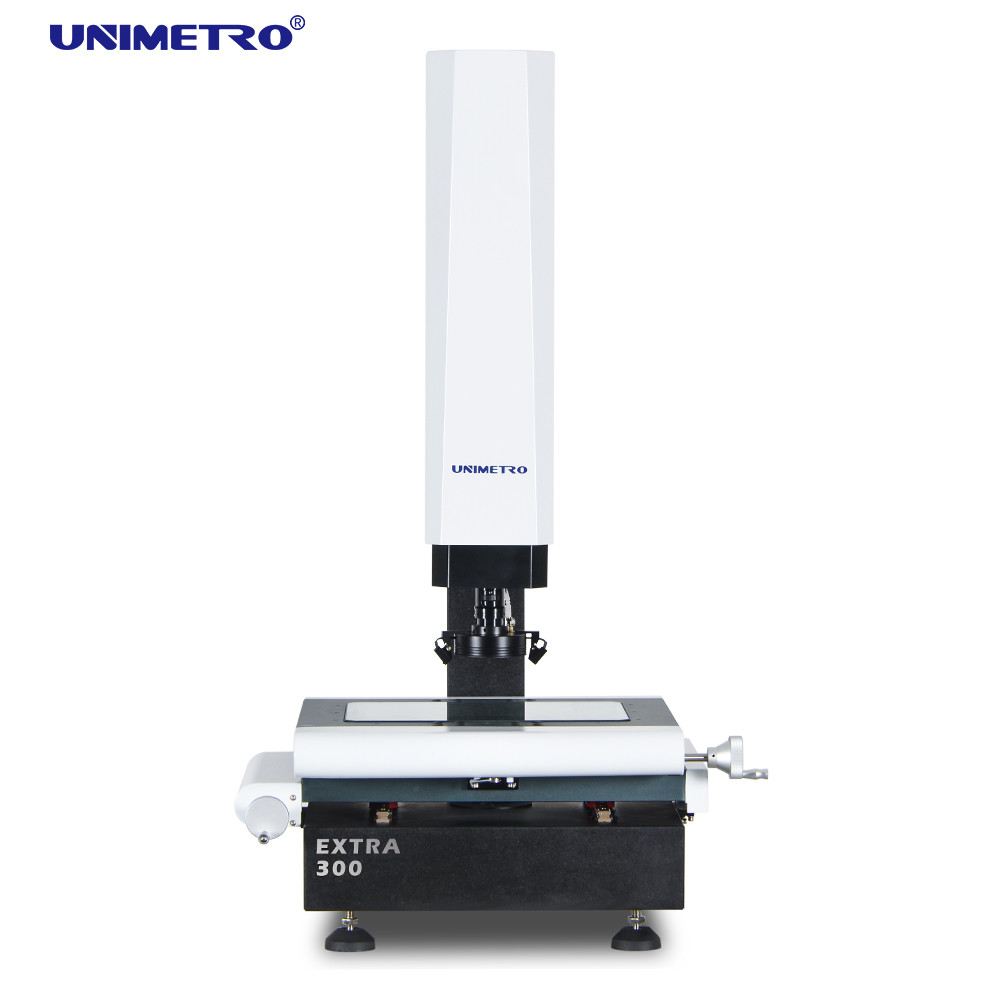

3) EXTRA series optical measuring machine is an important instrument used in your products quality control process. It ensures your products dimension accuracy, makes your products more competitive.

4) EXTRA Series vision measurement machine is designed and developed by UNIMETRO, which is a popular model fit for most of the accurate 2D dimension measuring application and end users from different industries, as Mold, Electronics, Semi conductor, Plastic Injection, 3C products, Medical care, Aviation...etc.

5) The Z axis of EXTRA series vision measurement machine is configured with close loop servo motor system, to achieve high accuracy movement control and auto focus function, users are able to control the Z axis movement and image focusing in the software or keyboard, highly increase the measuring efficiency.

6) The EXTRA series is innovatively configured with manual pulse generator for fine adjustment of the Z axis position, users can achieve Z axis fine adjustment and focusing easily.

--Comparing to the keyboard or joystick motion control, the MPG is more precise and sensitive, users can even move the axis micron by micron. Offering the best using experience for users.

--Z axis with high accuracy auto focus function, allows users to achieve fast and stable focusing operation, eliminating the focusing error caused by misjudgement or operators individual difference.

--Thanks to the high performance auto focus function, users can achieve height measuring function with the EXTRA series by non contact measuring.

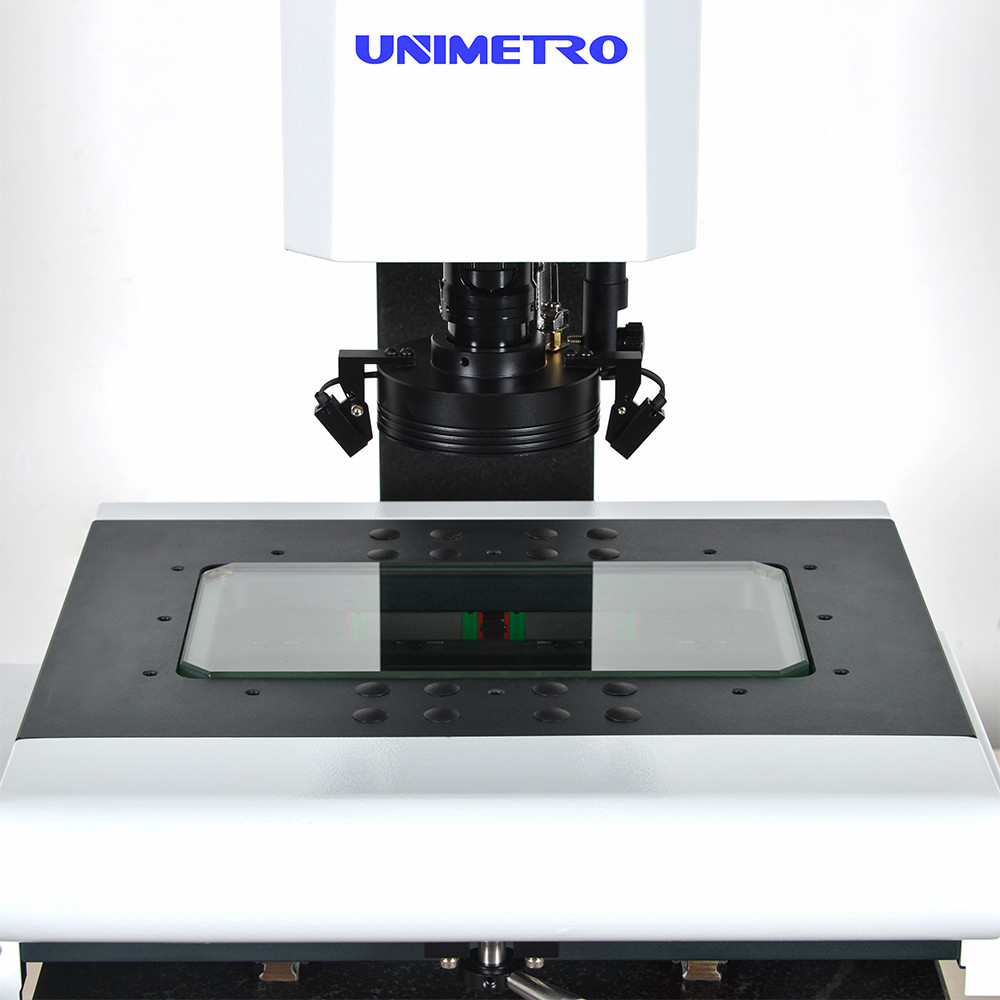

7) The EXTRA Series uses manual dented zoom lens with magnification signal feedback sensor, after users change the magnification, the software will select the suitable parameters automatically, user do not need to change parameters in the software and continue the measuring process. Which ensures a more convenient and time saving applicaiton.

--Configured with a 1.2M pixel HD digital camera, allows the users enjoy high quality image during the measuring process, highly increase the measuring accuracy. The Series is configured with high accuracy linear guide way, provides unique dynamic performance and end user experience. Also includes full programmable 8 sections LED surface illumination ring, 3 axis 0.0005mm high resolution linear transducers, and powerful measuring software.

a. Mould industry

b. Automobile manufacturing

c. Medical industry

d. Mechanical manufacturing

e. 3C digital industry

f. PCB production

Etc.

◉ 3 axis 0.5um resolution linear scales

◉ High performance Auto focus function

◉ Compatible with Renishaw touch probe

◉ Aluminum work stage and hard anodizing

◉ 3 rings 8 section LED ring light software control and programmable

◉ Parallel light path LED contour light software control and programmable

◉ 1.2M pixel HD digital camera

◉ Integrated core control box

◉ Z axis motorized control

◉ HIWIN linear guide way

◉ Manual pulse generator for Z axis movement control

◉ With Laser indicators for auxiliary positioning and focusing

◉ 0.7-4.5X manual dented zoom lens with magnification signal feedback sensor

Features

◉ Easy calibration

◉ Multiple angle touching

◉ Fast coordinates system setting

◉ Compatible to full line of Renishaw stylis

◉ CAD module supported(Optional)

◉ 3D drawing output

◉ Star probe compatible

◉ 3D dimension measuring

◉ Image and touch probe combine measuring

◉ Probe rack supported(Optional)

Parameters

| Model |

EXTRA 200 |

EXTRA 300 |

EXTRA 400 |

EXTRA 500 |

| Dimension(mm)(L*W*H) |

500*540*930 |

600*740*980 |

700*840*980 |

800*940*980 |

| Measuring range (mm)(X*Y*Z) |

200*100*150 |

300*200*200 |

400*300*200 |

500*400*200 |

| Measuring Accuracy (μm) |

2.5+L/100 |

2.5+L/100 |

2.5+L/100 |

3+L/100 |

| Repeatability (μm) |

2.5 |

2.5 |

2.5 |

3 |

| Weight (kg) |

140kg |

190kg |

240kg |

290kg |

| Image and Measuring |

CCD |

200mm (can be raised according to the requirements of customers) |

| Lens |

Manual dented zoom lens 0.7-4.5X/Auto zoom lens 1-10X |

| Magnification |

18-195X ( For reference only. With different camera and lens the magnification will be different. ) |

| Field of View |

8.1~1.3mm |

| Working distance |

108mm |

| Linear scale resolution |

0.5 μm( 0.1μm for option ) |

| Driving system |

X , Y axis manual conrol , Z axis close-loop CNC control and AUTU FOCUS funtion available |

| Illumination |

Programmable 4 sections LED ring surface light , parallel LED contour light , 8 sections LED ring light , co-axial , for option |

Software Function

powerful function, allows the users to achieve fast and precise measuring.

The software is offering full English language UI, also allows new language development.

◉ Input CAD file and measure

◉ Parts array and macro measuring

◉ Auto focus and height measuring

◉ Navigating function helps fast locating

◉ Powerful geometric measuring function

◉ Multiple data reports and graphical data output function

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!