Cell Phone LCD PCB 3D Measurement Software Automatic VMM Software Metal Plastic

Application

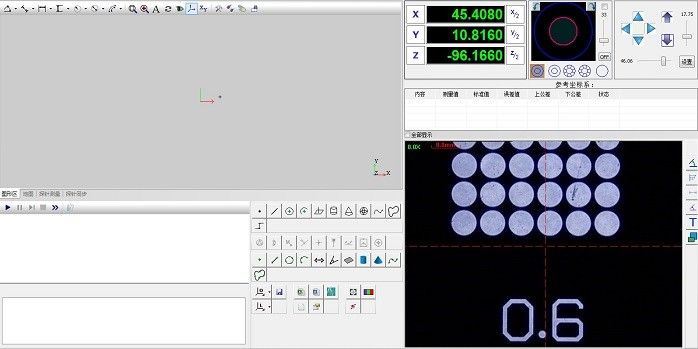

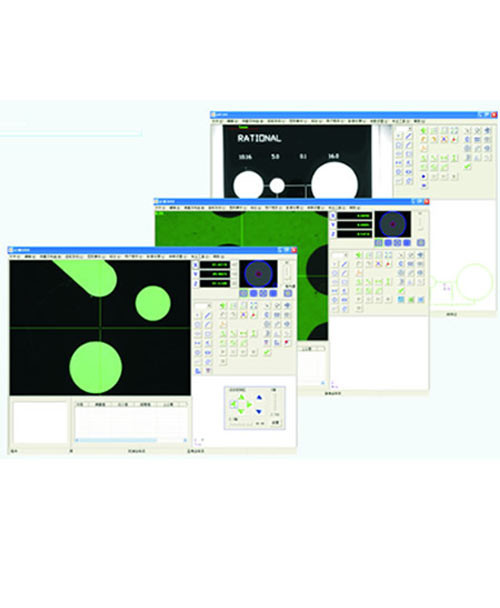

The Uins-2D series vision measurement machine software is a universal measuring software base on Windows operation system. Able to do the measuring and analysis on a measuring machine, widely used in multiple industries such as precise manufacturing, cell phone components, molding, electronics, communication, mechanical, plastic, PCB, LCD, etc. Able to measure the materials as metal, plastic, rubber, glass, PCB, ceramics, etc.

Features

Users design reports function included.

Offering fixture measuring, navigation function.

Powerful and flexible working stage control function, including X, Y, Z axis motion control, auto zoom lens control, auto focus, illumination control, offering multiple controlling mode for the X, Y, Z axis control.

Applied on CNC automatic vision measurement machine.

Offering vision measuring and construction tools, achieve the basic geometric elements measuring and constructing.

Able to output to Word, Excel, AutoCAD files.

Including SPC function, to achieve quality control.

Convenient and powerful users programming function.

Multiple language.

Function

Height measuring available.

Cross line capturing points.

Elements measuring and preset: points, line, circle, arc, grooves, ellipse, rectangle, ring, angle etc.

Elements constructing: center point, cross point, line, circle, angle, cloud line, etc.

Image processing: coordinates system offset, part alignment, axis alignment, coordinates system reset, circle zooming, image offset, graphic selecting and deleting, increasing the measuring efficiency.

SPC professional statistics and analysis software included, multiple diagram format offered.

Auto recording users program, learning executing mode.

Multiple language user interface.

Users can select multiple points measuring, fixed qty points measuring, zooming points collecting measuring based on requirement.

Company Information

Our Client&Agent

| FAQ |

Q1: Are you a factory or trading company ? Q1: Are you a factory or trading company ? |

A1: We are a factory and giving you the quickest reply in 24 hours. A1: We are a factory and giving you the quickest reply in 24 hours. |

Q2: What's your company mainly in? Q2: What's your company mainly in? |

A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. A2: We are mainly produce Vision measuring machine,Coordinate measuring machine ,CMM&VMM fixturesetc. |

Q3: How to Choose the Appropriate Specification? Q3: How to Choose the Appropriate Specification? |

A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. A3: As long as you tell us variety and size of product to be measured, our professional team would advise you of measuring instrument of suitable specifications. |

Q4: Do you accept customized service? Q4: Do you accept customized service? |

A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. A4: Be sure! We can provide not only typical machines, but also the machines customized to customer's needs. |

Q5: What is your warranty period? Q5: What is your warranty period? |

A5: Our product warranty period is 1 year. Our product quality is very stable, and we have A5: Our product warranty period is 1 year. Our product quality is very stable, and we have

improved a lot on some breakable parts. You can rest assured of our product quality. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!